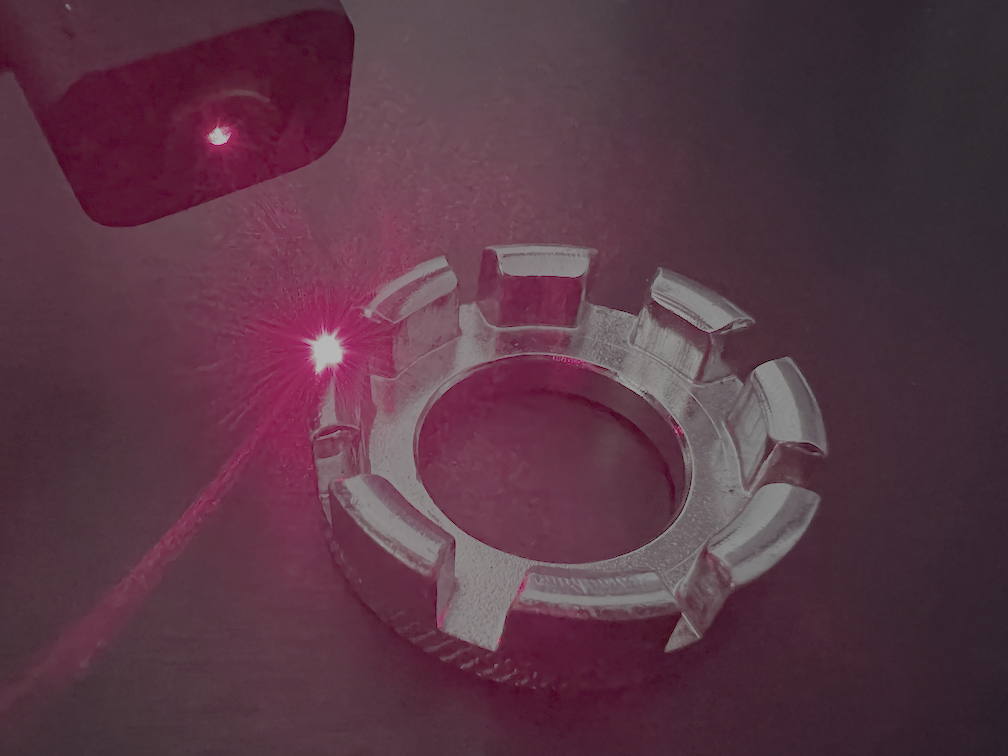

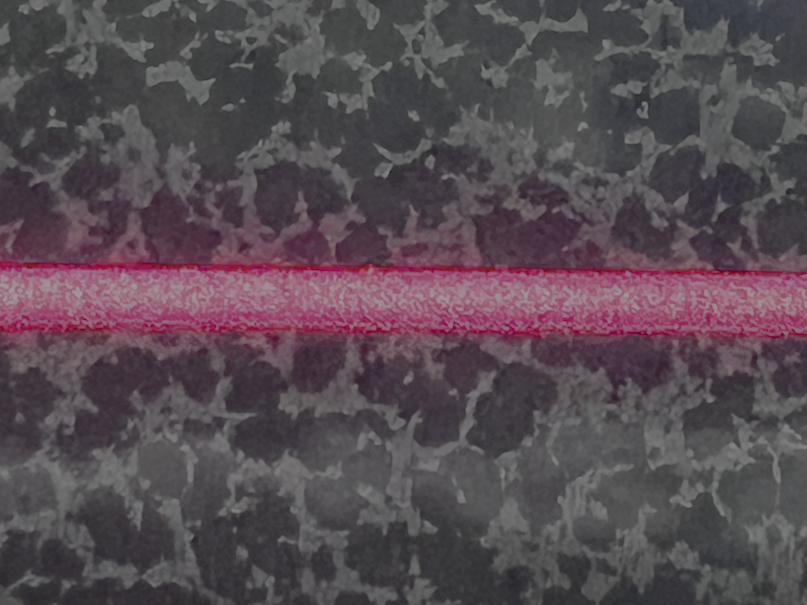

Optical non-destructive testing

Get reliable, non-contact data in real time.

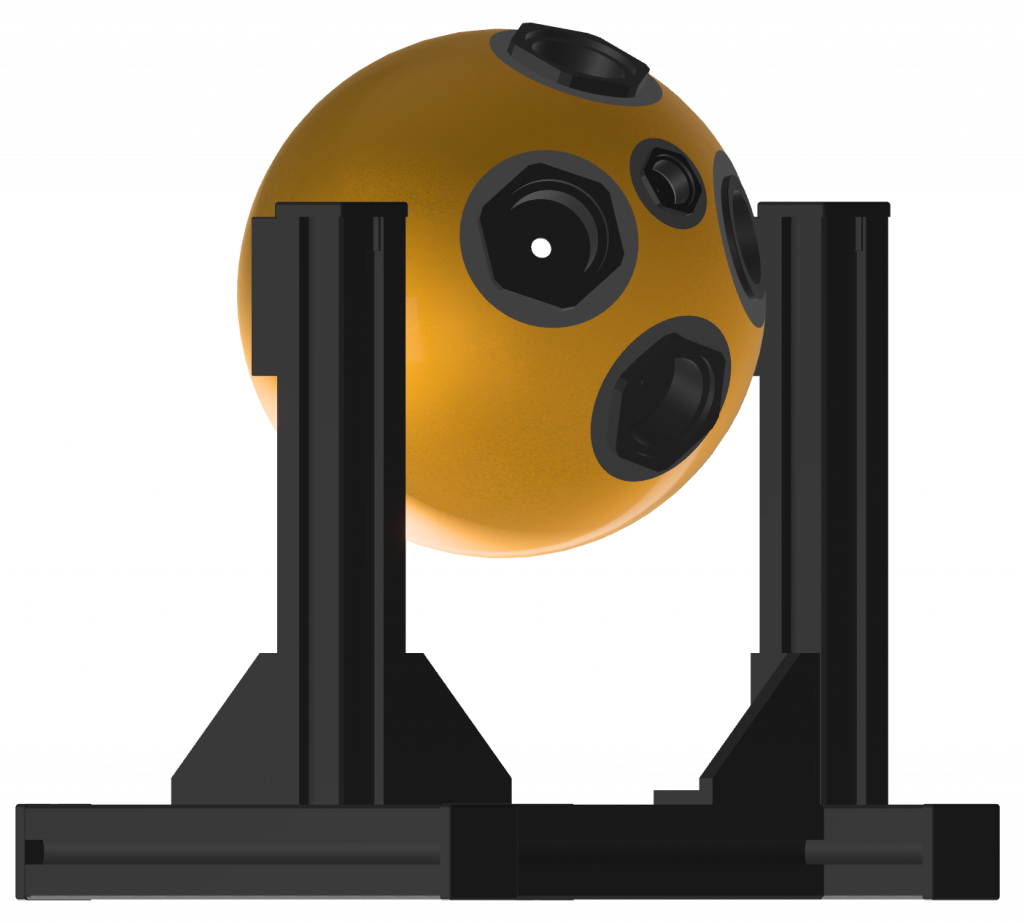

Imasolia designs advanced optical non-destructive testing systems to automate, make more reliable and enhance industrial control, from the laboratory to the production line.

We develop customized optical technologies to measure, inspect and qualify your products non-contactwith high precision and adaptability.

Our systems can be easily integrated into your production lines, test benches or R&D platforms, to meet the traceability, reproducibility and performance requirements of manufacturers.