Visual inspection plays a crucial role in modern industry, where the relentless quest for quality and efficiency is essential. It is a branch of Photonics, designed to modernize industry in particular.

This practice, long carried out manually, has undergone a major transformation thanks to technological advances. This article explores the role of visual inspection in the industry and the benefits of adopting innovative technologies.

The evolution of visual inspection

Traditionally, visual inspection has involved manual processes, requiring an attentive human eye (and therefore operator(s)) to detect defects and guarantee product quality. However, this method had limitations in terms of accuracy, human fatigue and production rate.

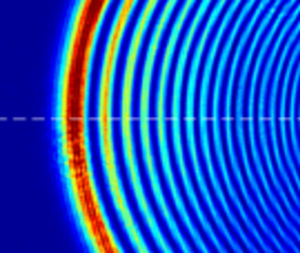

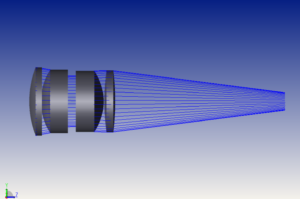

With the advent of computer vision and artificial intelligence, visual inspection has evolved towards automated methods. High-resolution cameras, sophisticated algorithms and advanced optical sensors have made it possible to achieve unprecedented levels of precision, while improving inspection speed.

The benefits of automated visual inspection

Greater precision

Automated inspection systems use algorithms to detect defects with micrometric accuracy, eliminating potential human error.

Time-saving

Machines can inspect products at a much faster rate than human operators, speeding up production and reducing downtime.

Reduced labor costs

By automating the inspection process, companies can reallocate manpower to more complex tasks, while reducing the costs associated with human error.

Improved traceability

Automated systems enable precise traceability of defects, facilitating reverse engineering of causes and ongoing process optimization. All inspections are stored in an optimized database for long-term archiving.

Use cases for automated visual inspection

In the automotive industry

In automotive manufacturing, automated visual inspection ensures component quality. This is the case for engine parts, welds and assemblies, reducing the risk of failure. Another example is visual inspection of paintwork.

In the food industry

Automated inspection systems are used to ensure the conformity of food products. In particular in terms of size, color and presence of impurities, thus guaranteeing food safety.

In electronics

For the electronics industry, automated visual inspection checks the quality of printed circuit boards, solder joints and connections. This ensures reliable electronic products.

In aeronautics

In the aerospace industry, visual inspection can be used to check the conformity and wear of certain critical parts. This field is a good illustration of the fact that objective criteria are difficult to meet when an operator is analyzing a part. An operator is de facto subject to human interpretation.

And many others, such as :

- The pharmaceutical industry,

- The luxury industry,

- The cosmetics industry,

- ...

In a nutshell

Automated visual inspection represents a major advance in industry, optimizing product quality, improving the efficiency of manufacturing processes and reducing costs. Companies that embrace this technology are better positioned to remain competitive in the global marketplace by meeting the highest quality standards.

Imasolia develops your visual inspection tools for industry

At Imasolia, we specialize in visual inspection in the industrial sector, using traditional vision tools combined with machinevision. With customized optical setups and the use of highly specific sensors, we'll adapt to your industry and use case.

We'll give you all the help you need to create a customized offer tailored to your needs. Just contact us.