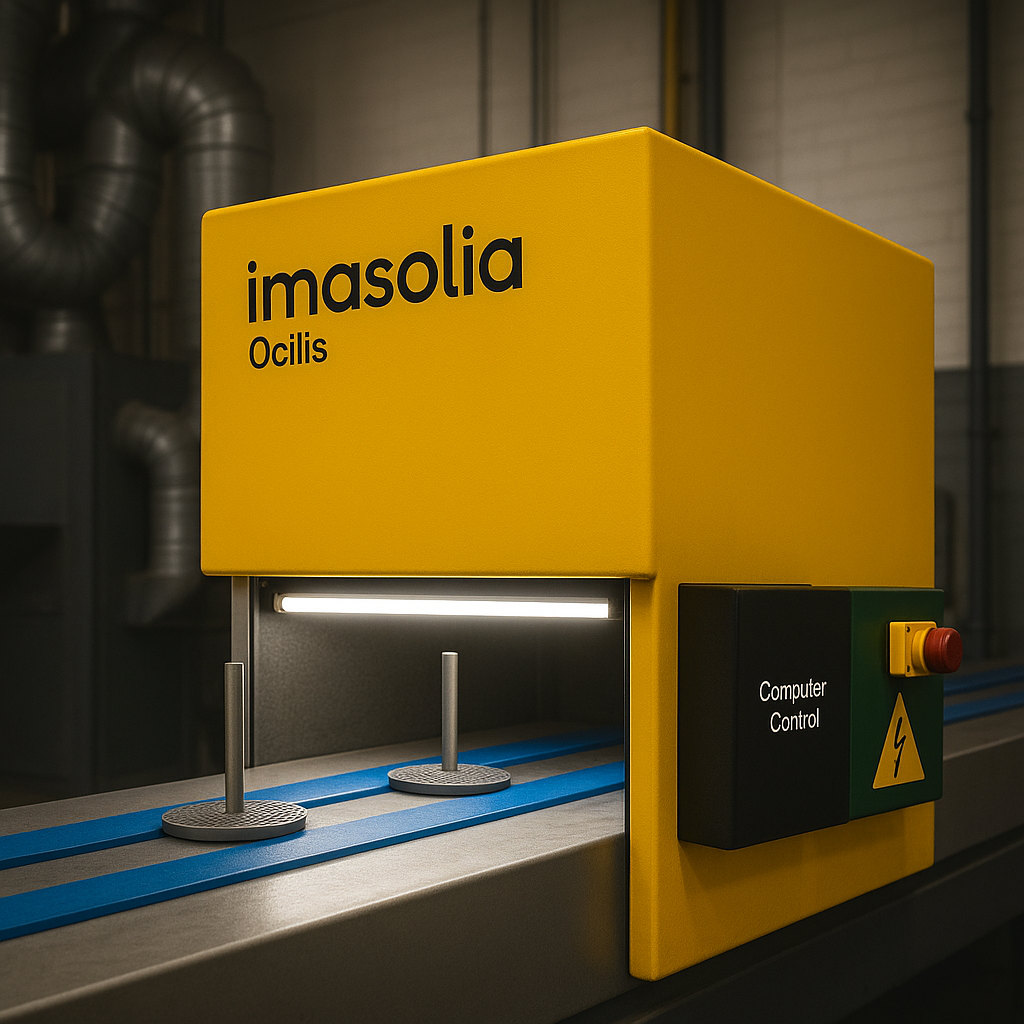

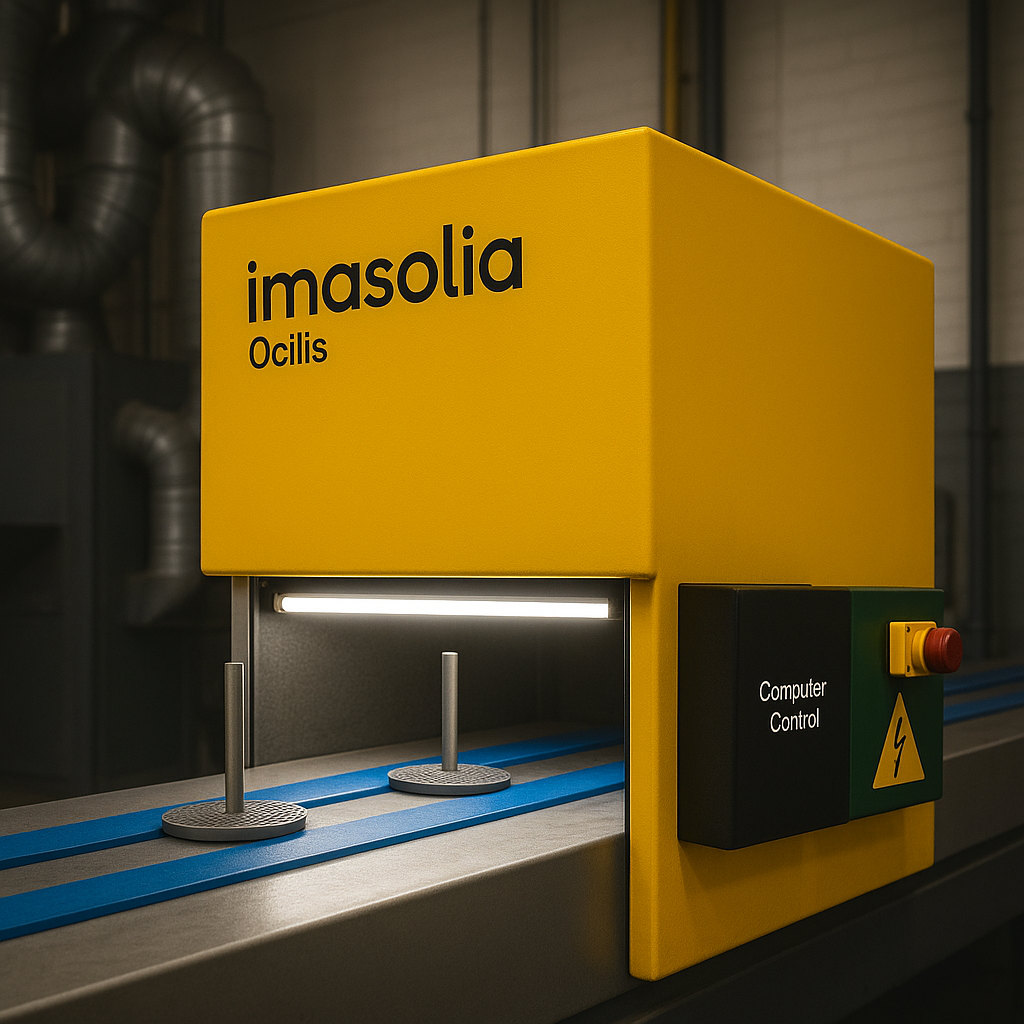

Ocilis: defect detection using machine vision

Automatic detection of defects and critical events using machine vision, to make industrial environments safer and more reliable.

Automatic detection of defects and critical events using machine vision, to make industrial environments safer and more reliable.

A modular platform for optimal quality control

Automatic real-time defect identification

Advanced non-contact imaging with AI algorithms

Multi-protocols CAN, IP, DIO for corrective actions

Standard or custom blocks according to your needs

Ocilis transforms your quality control with automated detection and real-time alerts.

Solutions tailored to industrial challenges

Quality control of machined or injection-molded parts

Detection of assembly defects

Verification of component presence and orientation

Production monitoring in extreme environments

Performance and industrial robustness

Detection type

Shape, appearance, position, texture

Inspection speed

Up to 200 pieces/min

Resolution

Up to 5 µm

Protocols

CAN, IP, DIO

Integration

Embedded or fixed systems

Contact our team for a personalized demonstration